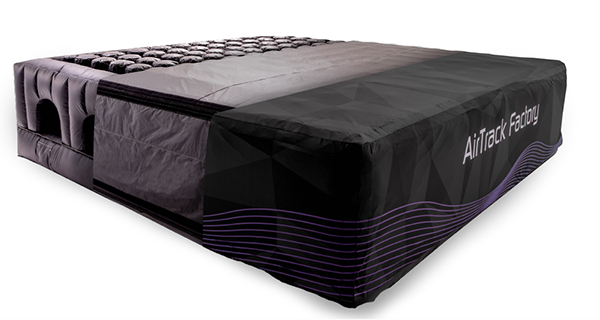

1. SIDEWALLS – Our airbags have “Roman Arch” sidewalls which prevent the collapsing of the AirBag around its perimeter that you see in most of our competitors airbags. This is also why our AirBags have the sharper tight look, and aren’t saggy and wrinkled looking.

Interior View of the AirBag, the Cover & the Top Sheet

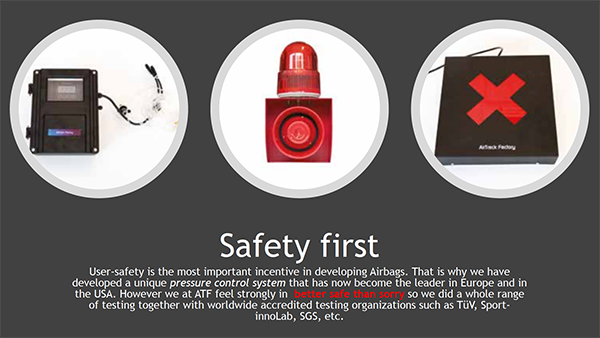

2. PRESSURE CONTROL – We have a new pressure control system that gives gym owners and coaches the ability to control the AirBag pressure from the top side of the pit instead of having to crawl down in a pit to look for ventilation flaps to open in our competitor’s AirBags.

3. PRESSURE ALARM – Our alarm system constantly monitors the AirBag pressure and sets off a visual and auditory alarm if the pressure dips below a predetermined value. In contrast, some other alarm systems only monitor the power to the blower.

4. DURABILITY – We use a thicker layer of PVC on our AirBags (and AirTracks), without any inactive fillers (like chalk for example), than are typically used by other manufacturers.

5. VERSATILITY – It is important that we constantly monitor the needs of the industry. We are always looking for unique ways to enhance our products. We’ve added a variety of features to our AirBag to allow for more versatility, such as the addition of lifting bags. With the flip of a switch, our AirBags can raise or lower in height, allowing for different drills and/or different levels of training.

AirBag with Multiple Lifting Bags

6. PORTABILITY – We have designed portable AirBag units specifically for gymnastics training that are simple to move around the gym, as compared to large resi mats.

Small Portable Gymnastics AirBag

7. QUALITY CONTROL – We have a firm Quality Control (QC) process. Our in-house design team will create initial drawings of your AirBag for your approval, and then our manufacturing team creates detailed technical drawings for you to sign off on. Every component of every AirBag order is measured, thoroughly pressure tested and everything recorded for our team to review before it is released for shipping. Every AirBag is assigned a unique number, which allows us to trace back all components if necessary.

8. MANUFACTURING CONTROL – The AirTrack Factory manufacturing facility is 80,000 sqft and only produces our “air” product lines. In contrast, a lot of our competition outsource their manufacturing to facilities that make large quantities of bouncy houses, inflatable Kayaks/surfboards, etc, and then make an “airbag” or “airtrack” product using those same materials and production methods. AirBags and AirTracks are obviously completely different products for completely different purposes than bouncy houses and inflatable kayaks, and therefore require much more rigid manufacturing processes and quality control.

AirTrack Factory Production Facility

9. CUSTOMIZABLE – We can design and manufacture custom shape and size AirBags for just about any purpose, providing cutouts for columns or trussing, as well as irregular shapes to fit unique areas in your facility.

10. FOAM TOPPER – We make a foam topper with a soft touch denim fabric cover that velcros to the top of your AirBag and can provide a safe pillow-soft landing surface.

11. GYMNASTICS EXPERTISE – One of the most important aspects about our company is we are experts in the sport of gymnastics. We aren’t an inflatable company simply looking to push another product. We are a gymnastics-based company founded by former National & World Team Member gymnasts who know the sport inside and out. We can speak the language and can make solid recommendations based on the type of training offered at your facility and the specific apparatus for which your AirBag(s) will be used.

12. WARRANTY – Our AirBags all have a 2-year warranty for any manufacturing defects.

Leave A Comment